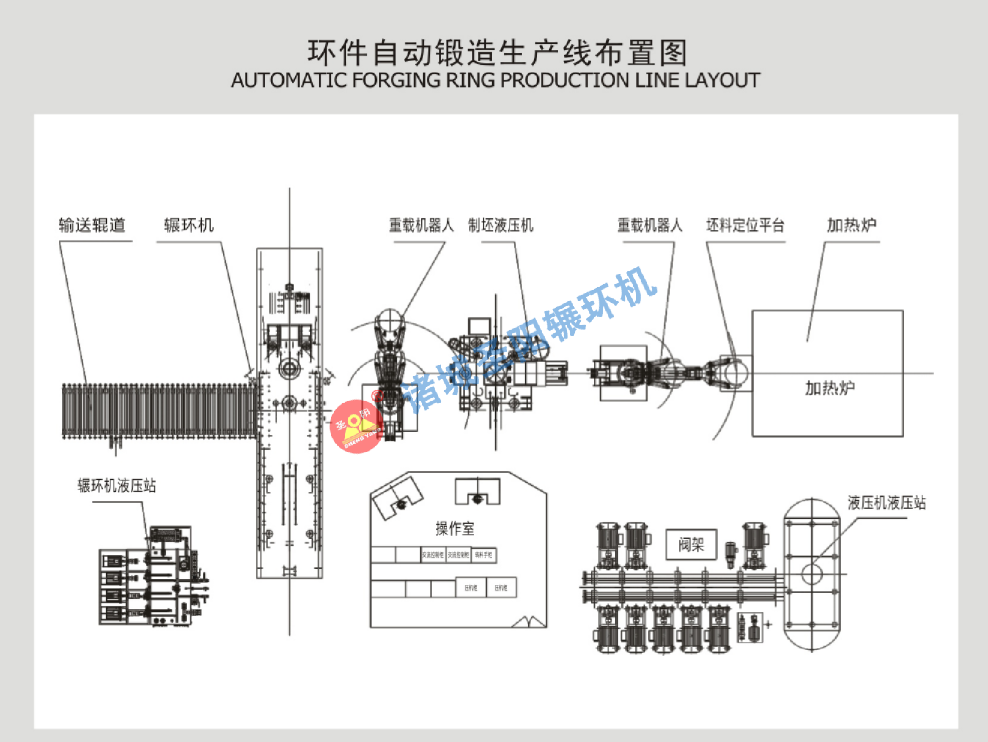

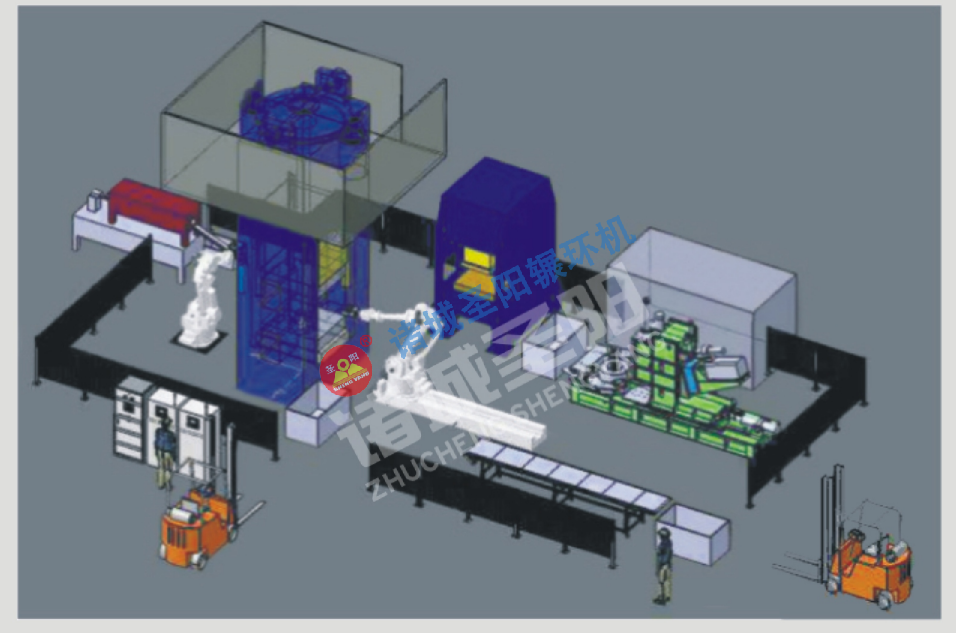

环件自动锻造生产线构成︰搬运原材料的装取料机、用于开坯的油压机、坯料搬运及定位的机械手、进行环件轧制的数控径轴向辗环机、环件搬出的机械手、对环件翘曲进行矫正的矫正压机等。本生产线各单机之间能够实现联动操作控制,坯料环件可自动进行输送、搬运、定位轧制、在线检测,实现了环件锻造过程自动化。本生产线能与工厂的管理层进行联网,显示终端能对生产线的运行状态进行监控,若监控员监控到故障能通过网络通知现场的维护人员及时进行维护。

Automatic forging ring production line consist of loading manipulator used to carrying material, hydraulic pressmachine used to make blank,forging manipulator used to clamp blank, radial-axial CNC ring rolling machineused to produce ring, manipulator used to unloading ring, corrective press machine used to correct warpingring.

All equipment can realize associated action, material and product can be carried, transported, located, rolledand online inspected,make automatic forging ring production line into reality. This production can beconnected with management network, live broadcast on monitor,supposing malfunction happened monitorman can tell maintain man remove it in time.

鲁ICP备16048201号-1

鲁ICP备16048201号-1